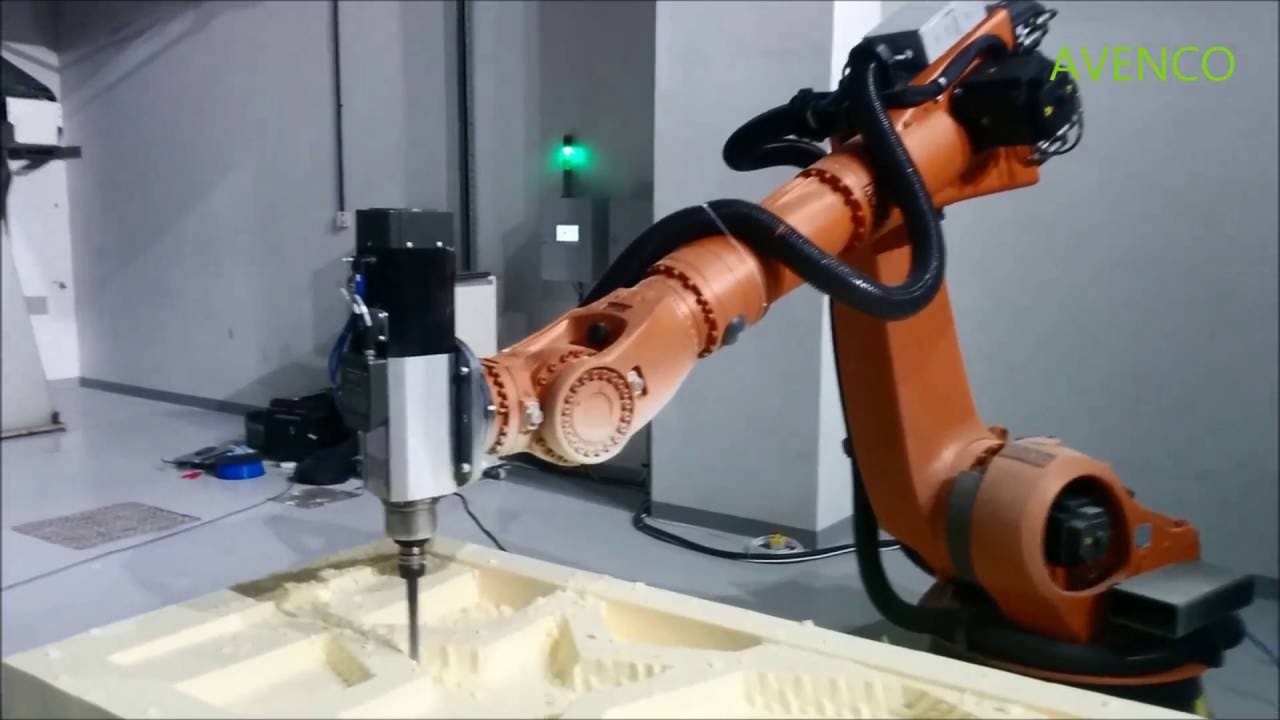

Machining and Milling Applications

CNC – “Computer Numerical Control” in other words “Computer Numerical Management” has a share in the production of everything we use today. These systems, which play an active role in the processing of metal, wood, a wide variety of plastics and natural/artificial stones, have accelerated the manufacturing processes. At the same time, they have enabled the production of standardized products. Due to their mechanical structure, the size limits of the parts they process have emerged, and this situation has been solved with bridged and larger CNCs. Now, industrial robots, which are mechanically very different from the CNC machines that we imagine in our minds and work with NC programs, have started to take their place in production. Developing production capabilities can easily transform a robot into a CNC of tens of meters.

Main features of the systems we have commissioned;

- Material: Aluminum, Brass, Marble, Wood, XPS, Fiber, Epoxy, Various Plastic

- Machinery and Equipment: Robot, Rail, Rotary Table, Tool Changing Table, Automatic Tool Calibration Set, Water/Air Cooled Spindle, Cooling Unit

- Program: CAM Support with Sprutcam Program, Postprocessor Support for KUKA.CAMROB, KUKA.CNC and other brand robots

- Application: Sculpture, Aviation Mold Production, Yacht Mold Production, Architectural Mold Production